Dual probe metal detector

Product introduction

Dual

probe metal detector can detect all metal contaminations including ferrous,stainless

steel, copper, aluminum etc from packing finished product or material. Once

dual probe metal detector detects the metal contamination, the alarm bell will

work and the belt will stop, and then workers can eliminate the unqualified

product artificially. Dual probe metal detector use the newest model detecting

coil technology, the range of detectable metals is very wide and the ability is

very strong, and the size of machine is small and short, so it’s suit to

integrated on belt system.

Product suitable for:

|

- lump

material(including parked finished product or bulk material)

|

Installation place:

|

|

Applications:

|

- food

industry, chemical industry, pharmaceuticals industry, textile industry,

packaging industry and other industries.

|

Product features:

|

- The newest detecting coil (

the non-metal area is smaller), UV stainless steel structure, stable, good

performance, long life; fit the hygiene requirement of food industry, easy

disassemble and assemble, easy cleaning.

- Obvious

effect when detecting the product and can be adjusted to low frequency

processing technology when used for special packing product.

- Dual probe design, make the

detection strengthen .

|

Product advantages:

|

- Special

conveys system design, make the metal sensibility maximize.

- Modular design, flexible

customize based on different requirements.

- UV

stainless steel, open style transport system and easy cleaning.

- Satisfy

the certification requirement of IFS and HACCP, has different kinds of reject

model for choosing based on different kinds of application, such as FLIP,

contraction band and so on.

|

System composition:

|

- Detection

system: dual probe, dual channel metal detection coil, rectangle caliber.

- Control

system: ADLINE Micro Process controller.

- Conveyor:

all-welded, high strength stainless steel structure, integrated type

PU(polyurethane) conveyor.

- Motor:

90W dynamo, reduction gearbox integrated.

|

Typical application:

|

- packed

detection (the last metal detection before delivery, detection when weighting

and labelling.)

|

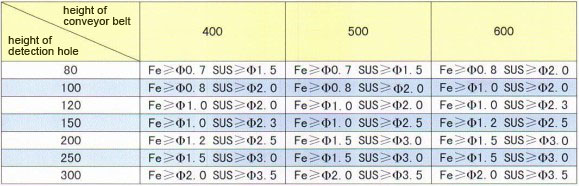

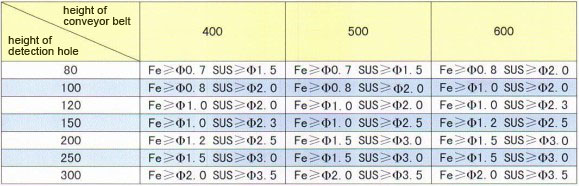

Technical parameters:

|

|

The sensibility of dual

probe metal detector:

All

sensors above are idling and non-environment disturbance condition, the reality

maybe a little difference.